Concrete Pipe Seals

Concrete pipe seals provide crucial waterproofing and structural integrity for underground piping systems, ensuring durability and preventing leaks.

Concrete Pipe Seals

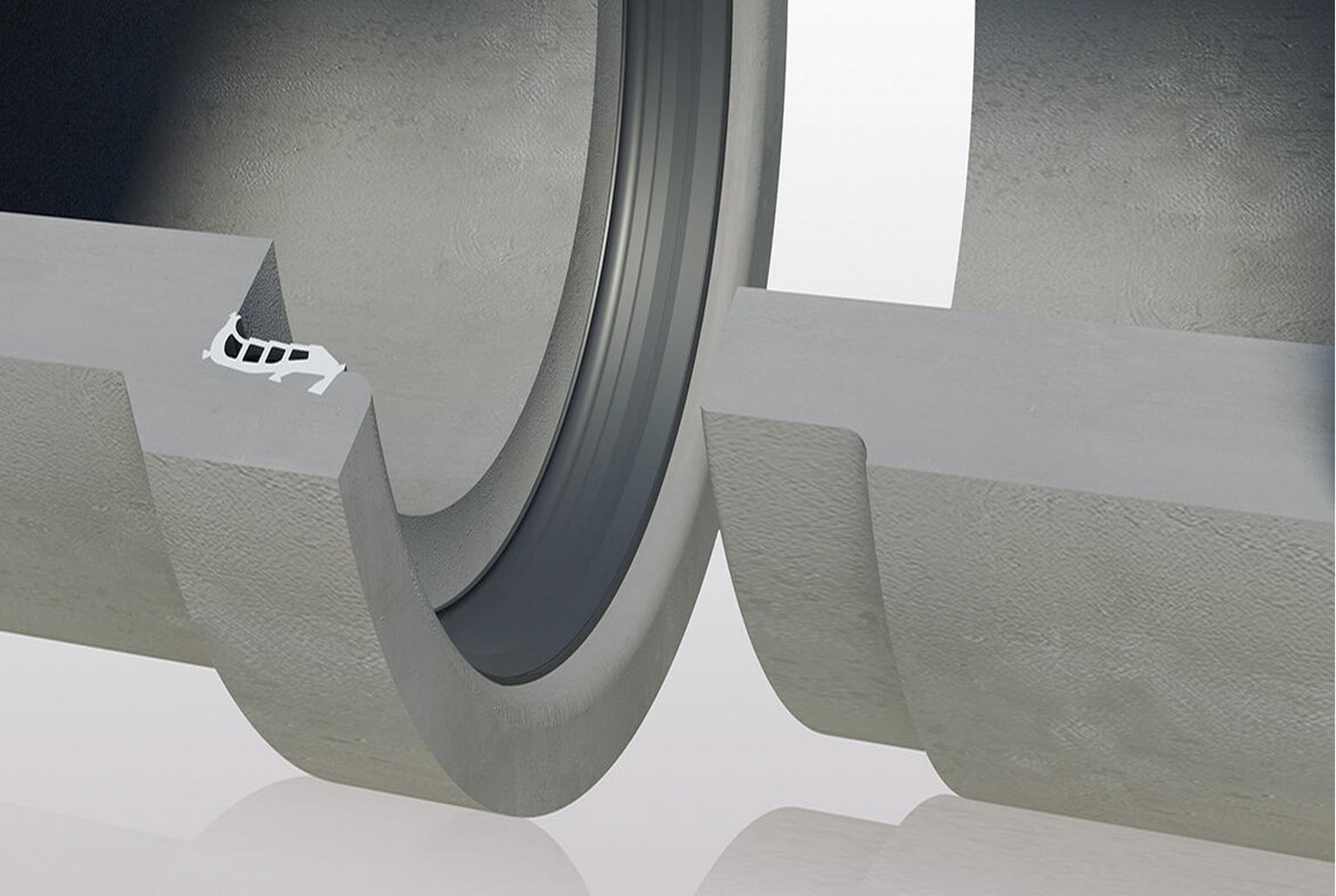

Concrete pipe seals are essential components used in the construction and maintenance of underground pipe systems, particularly in sewer, drainage, and water distribution networks. These seals play a crucial role in ensuring the integrity and efficiency of the piping infrastructure by preventing leakage, infiltration, and exfiltration of fluids, as well as providing structural support and stability to the pipeline.

Typically made from high-quality rubber or elastomeric materials, concrete pipe seals are designed to withstand a wide range of environmental conditions, including temperature variations, chemical exposure, and mechanical stress. They are engineered to maintain their flexibility, resilience, and sealing properties over extended periods, even when subjected to harsh operating conditions.

The design of concrete pipe seals varies depending on the specific application and requirements of the pipeline system. Common types of seals include:

-

O-Ring Seals: O-ring seals are circular elastomeric rings with a cross-sectional shape resembling the letter “O”. They are widely used in concrete pipe joints due to their excellent sealing performance and ease of installation. O-ring seals provide a reliable compression seal when compressed between two mating surfaces, effectively preventing the passage of fluids along the pipe joint.

-

Gasketed Seals: Gasketed seals consist of flexible gasket materials, such as rubber or synthetic elastomers, encased within a rigid frame or channel. These seals are designed to fit into specially designed grooves or recesses in the pipe joint, forming a tight and durable seal when the pipe sections are assembled. Gasketed seals offer superior resistance to deformation and extrusion under pressure, ensuring long-term sealing integrity.

-

Compression Seals: Compression seals are composed of compressible elastomeric materials that are compressed between the mating surfaces of concrete pipe joints. These seals rely on the applied compression force to deform and create a tight seal against the pipe walls, effectively blocking the passage of fluids. Compression seals are often used in joints subjected to high-pressure conditions or where significant movement or settlement is anticipated.

-

Lubricated Seals: Lubricated seals utilize lubricants or sealants applied to the sealing surfaces to reduce friction and enhance sealing performance during joint assembly. These seals are commonly used in large-diameter concrete pipes or where tight tolerances make joint assembly challenging. Lubricated seals facilitate easier installation and improve the effectiveness of the sealing system.

-

Wraparound Seals: Wraparound seals are flexible strips or sheets of elastomeric material that are wrapped around the exterior of the pipe joint and secured in place using mechanical fasteners or adhesives. These seals provide an additional layer of protection against water infiltration and corrosion, particularly in joints exposed to aggressive soil conditions or corrosive environments.

In addition to their sealing function, concrete pipe seals also contribute to the structural integrity and stability of the pipeline system by distributing loads, absorbing vibrations, and accommodating thermal expansion and contraction. Proper selection, installation, and maintenance of concrete pipe seals are essential to ensure the long-term performance and reliability of underground pipe networks, minimizing the risk of leaks, collapses, and other costly failures.