Aluminium Rubber

Aluminum rubber combines the lightweight, durable properties of aluminum with the flexibility and sealing capabilities of rubber for versatile applications.

Aluminium Rubber

Aluminium rubber, also known as aluminum rubber or aluminum-filled rubber, refers to a composite material composed of rubber or elastomeric matrix reinforced with aluminum particles or fibers. This unique combination of materials offers a wide range of mechanical, thermal, electrical, and chemical properties, making it suitable for various industrial, automotive, aerospace, and electronic applications.

The composition of aluminum rubber typically consists of rubber or elastomeric polymers such as natural rubber (NR), styrene-butadiene rubber (SBR), ethylene propylene diene monomer (EPDM), silicone rubber (VMQ), or fluorocarbon rubber (FKM), blended with aluminum particles, flakes, or fibers. The aluminum component may be pure aluminum or aluminum alloys such as aluminum-magnesium (Al-Mg) or aluminum-silicon (Al-Si) alloys.

The key properties and characteristics of aluminum rubber include:

-

Mechanical Properties: Aluminum rubber exhibits excellent mechanical properties such as high tensile strength, tear resistance, flexibility, and durability. The rubber matrix provides elasticity and resilience, while the aluminum reinforcement enhances stiffness and strength, resulting in a composite material with superior mechanical performance.

-

Thermal Conductivity: The presence of aluminum particles or fibers in the rubber matrix enhances the thermal conductivity of the composite material. This property makes aluminum rubber suitable for applications requiring efficient heat transfer, thermal management, or dissipation of heat generated during operation.

-

Electrical Conductivity: Aluminum rubber can exhibit electrical conductivity due to the presence of conductive aluminum particles or fibers dispersed within the insulating rubber matrix. This property makes it suitable for applications requiring electromagnetic shielding, static dissipation, or electrical grounding.

-

Chemical Resistance: Aluminum rubber offers good resistance to a wide range of chemicals, oils, fuels, solvents, and environmental conditions. The rubber matrix provides protection against corrosion, abrasion, and degradation, while the aluminum reinforcement enhances the material’s resistance to chemical attack and environmental exposure.

-

Lightweight: Despite the addition of aluminum particles or fibers, aluminum rubber remains relatively lightweight compared to solid metal counterparts. This lightweight characteristic makes it suitable for applications where weight reduction is desirable, such as automotive components, aerospace structures, and electronic enclosures.

-

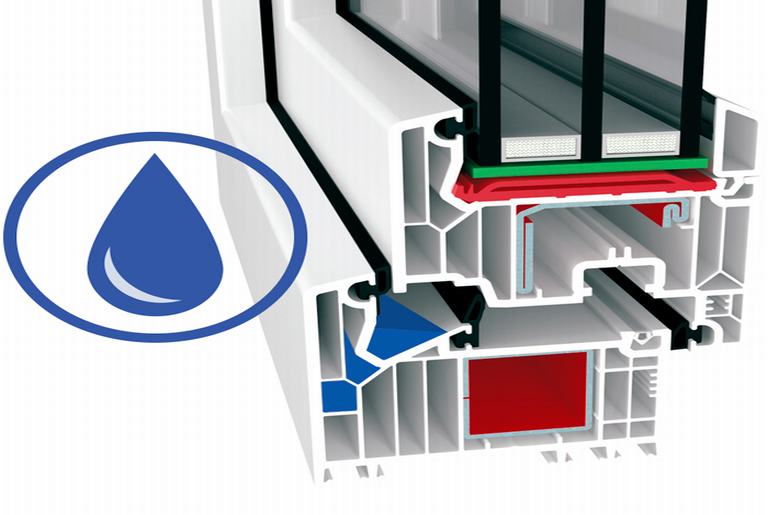

Sealing and Gasketing: Aluminum rubber is often used in sealing and gasketing applications due to its excellent compression set resistance, sealing performance, and ability to conform to irregular surfaces. It provides effective sealing against fluids, gases, dust, and environmental contaminants, making it ideal for use in automotive engines, machinery, pipelines, and aerospace systems.

-

Vibration Damping: The combination of rubber’s damping properties and aluminum’s stiffness results in a composite material that offers effective vibration damping and noise reduction. Aluminum rubber is commonly used in vibration isolation mounts, shock absorbers, and noise control applications to attenuate mechanical vibrations and noise.

Applications of aluminum rubber span across various industries and sectors, including:

-

Automotive: Seals, gaskets, hoses, engine mounts, suspension bushings, vibration isolators, and weatherstripping.

-

Aerospace: Seals, gaskets, insulation, vibration dampers, thermal barriers, and electromagnetic shielding.

-

Electronics: EMI/RFI shielding gaskets, thermal interface materials, flexible circuit substrates, conductive seals, and connectors.

-

Industrial: Seals, gaskets, expansion joints, conveyor belts, vibration isolators, damping pads, and die-cut components.

Overall, aluminum rubber offers a versatile and multifunctional solution for a wide range of engineering challenges, combining the mechanical properties of rubber with the thermal and electrical properties of aluminum to meet the diverse requirements of modern industrial applications.